+91-8828813630

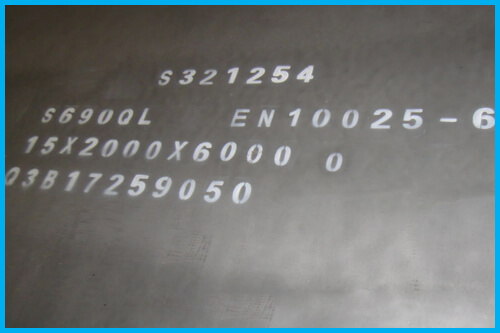

S690 QL

S690 QL, S690 QL high yield Steel plates, High strength steels S690 QL Plates

S690 QL is a high return structural steel evaluation created in consistence with EN 10025:6:2004.

S690 QL, S690 QL high yield Steel plates, High strength steels S690 QL Plates.

S690 QL material is high temperature treated utilizing the extinguish and temper transform and has great bowing and welding properties.

Because of the materials high quality nature, utilizing S690ql will advance leaner outlined structures with expanded payload limit and vitality proficiency.

Offering an extensive variety of overwhelming work structural steel for our clients. Scaffold plate and building structure boards steel sheet are accessible in different evaluations like straight review, low carbon evaluation and high carbon evaluation as indicated by the prerequisite of our client.

It would be ideal if you allude to the specialized subtle elements beneath alluding to S690 QL.

S690 QL Plate, S690 QL Plate Suppliers,S690 QL Plate Manufacturers, S690 QL Plate Stockists, S690 QL Plate Exporters,S690 QL Plate Traders, S690 QL Plate Dealers, S690 QL Plate Importers, Authorised Distributors Of S690 QL Plate, Authorised Exporters Of S690 QL Plate, Authorised Traders Of S690 QL Plate, Authorised Importers Of S690 QL Plate, Autorised Suppliers Of S690 QL Plate. S690QL Plates, EN 10025-6 Steel Plate, S690 QL EN 10025–6 structural steel Plates, High yield EN10025 Grade S690 QL Plates, Dillimax 690 T Plates Exporters, Suppliers and Stockists in India.

S690 QL Plate Manufacturers in Mumbai, S690 QL Plate Suppliers in Mumbai, S690 QL Plate Stockists in Mumbai, S690 QL Plate Exporters in Mumbai,S690 QL Plate Traders in Mumbai , S690 QL Plate Dealers in Mumbai, S690 QL Plate Importers in Mumbai, Authorised Distributors Of S690 QL Plate in Mumbai, Authorised Exporters Of S690 QL Plate in Mumbai,Authorised Traders Of S690 QL Plate in Mumbai, Authorised Importers Of S690 QL Plate in Mumbai,Autorised Suppliers Of S690 QL Plate in Mumbai. EN 10025-6 S690QL High Strength Steel Plates, S690QL Hot-Rolled Heavy Plates Stockholders, S690 QL EN 10025–6 Quenched and tempered structural steel Plate Dealers & Distributors in Mumbai.

S690 QL - Grade Designation

The grade designation of S690 QL is the following: S = Structural Steel

690 = minimum yield strength (MPa)

Q = Quenching & Tempering

L = Low notch toughness testing temperature

CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | N | B | Cr | Cu | Mo | Nb* | Ni | Ti* | V* | Zr* |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S690 QL | 0.20 | 0.80 | 1.70 | 0.025 | 0.015 | 0.015 | 0.0050 | 1.50 | 0.50 | 0.70 | 0.06 | 2.0 | 0.05 | 0.12 | 0.15 |

MECHANICAL PROPERTIES

| Designation | Mechanical Properties (ambient temperature) | |||||||

|---|---|---|---|---|---|---|---|---|

| Steel Name | Steel Number | Min. Yield Strength Reh MPa | Tensile Strength Rm MPa | Min. % elongation after fracture | ||||

| Nominal thickness (mm) | Nominal thickness (mm) | |||||||

| ≥3 ≤50 | ≥50 ≤100 | ≥100 ≤150 | ≥3 ≤50 | ≥50 ≤100 | ≥100 ≤150 | |||

| S690 QL | 1.8931 | 690 | 650 | 630 | 770/940 | 760/930 | 710/900 | 14 |

V NOTCH IMPACT TESTING

| Grade | Sample Orientation | @ 0°C | @-20°C | @-40°C | @-60°C |

|---|---|---|---|---|---|

| S690 QL | Longitudinal | 50 J | 40 J | 30 J | –– |

| Traverse | 35 J | 30 J | 27 J | –– |

APPLICATION

Machine building

Lifting equipment

Heavy transportation

Steel constructions

S690 QL Plate Manufacturers in India, S690 QL Plate in India, S690 QL Plate Suppliers in India,S690 QL Plate Stockists in India, S690 QL Plate Exporters in India, S690 QL Plate Traders in India, S690 QL Plate Dealers in India, S690 QL Plate Importers in India, Authorised Distributors Of S690 QL Plate in India, Authorised Exporters Of S690 QL Plate in India,Authorised Traders Of S690 QL Plate in India, Authorised Importers Of S690 QL Plate in India, Autorised Suppliers Of S690 QL Plate in India.

Download S690 QL PDF

View S690 QL PDF